The product packaging process has changed a lot over the past few years. As the world evolves, so does the packaging process. This change can be attributed to three main areas:

- Manufacturing and Technological Change

- Financial investment terms and brand equity

- Shifts in consumer buying habits

For this reason, we have developed quad seal bags to meet your needs. Made from high-quality materials, they are versatile and have several advantages over other bags. If packaging quality is your concern, whether as a manufacturer, retailer, or store owner, this guide will guide you to the ultimate solution for quad-seal pouch-based consumer packaged goods (CPG).

1. What is a quad-seal bag?

Quad sealed bags are also called corner-sealed bags, quad seal pouches. They feature four corners on the bottom, giving these bags a reinforced structure that helps them sit well, increases their stability on shelves, maintains their stylish shape, and ultimately keeps them unique sex. The bottoms of these pouches mimic regular boxes. This base construction is one of the main reasons they are known as the most stable bags on the shelf. The four-pocket openings are resealable and provide plenty of room when you’re filling or refilling. The custom manufacturing process gives these handbags the eye-catching quality and stylish look that is much loved by the clients.

Plus, these are multipurpose bags; you can use them to carry and store a variety of items. Are you concerned about how to store flour, grains, chemicals, or any product in a controlled or favorable environment free from contamination? Don’t worry. The quad-seal bag is here for you. Chapter 2 of this guide will explain in detail how to use these fancy pouches. Depending on your purpose or use, you can choose any one of the quad-seal bags among various types produced in our factory. Chapter 5 covers the different types in detail. The materials and workmanship of these stylish handbags are not only pleasing to the eye. Professionalism, care to detail, and perfection of use help to provide all the safety and required protection features required for product storage, transport and attraction.

2. 6 Advantages of Quad Sealed Bags?

Unlike other types of bags, quad seal bags are useful for you as a customer, retailer, shop owner, grocery retailer, fruit seller, or manufacturer. Have you ever been frustrated with poor-quality bags? Take a deep breath; the quad-seal bag is here for you. These bags are of high quality and will never let you down. The only concern is you. When ordering quad gusset bags, you must provide details about how you intend to use the bags. With help like this, we can make a product that’s right for you. If you need to store acidic products, you need to be informed. Placing an acidic product in the wrong bag can lead to unintended oxidation, which can lead to spoiled flavor. Below is a glimpse of the benefits of the quad-seal bag.

1) Design

Are you a retailer or a manufacturer? If yes, then you understand how important product packaging is to your customers. Good product packaging can attract and entice customers to buy a product. Therefore, the label, print, and text on this bag can be customized according to your branding. Any custom imprint can be professionally printed on any bag. The well-designed quad seal bag also doubles as a billboard. As opposed to standing pouches without gussets, here you have almost five sides to inform and attract your customers. You can choose to use the gussets on the sides, the back, and the front panel and if you prefer the bottom, you can create the visual impression as you wish.

You can draw pictures and write intuitive messages that will entice customers from far away to buy your products. This will put you ahead of your competitors. Second, you will have the opportunity to tell them about your product benefits. A well-designed gusset bag can really attract customers and demonstrate the quality of your product.

2) Easy storage

With a rectangular bottom and upright features, the quad seal bag fits comfortably on any shelf. This allows for more bags to be arranged on one shelf, as opposed to what you would store if you were using other bags such as pillow bags, boxes, or other bags. The knowledge, philosophy, and expertise that go into the production of this bag ensure that the inflatable bottom lays flat when full or half full. The gusseted base allows these stylish bags to stand still on the shelf for as long as possible.

3) Solid

They can hold heavy-duty products thanks to the materials used in quad seal bag manufacture and bottom reinforcement. You’ll take these bags anywhere without worrying about tearing. Are you tired of using poor-quality bags that constantly break your mind? Quad seal bags are made from multi-layer and laminated films to ensure optimum performance whatever their application. If you need a pouch that fills its capacity from bottom to top, look no further. These bags are sustainable and don’t waste storage space. As long as you order the correct type of quad seal bags, you can use them however you want. Customers are there looking for products that will look great on kitchen shelves or perfect for home storage. The prominent features of these bags that mimic boxes will increase the attractiveness of your products to customers.

4) Cost-effectiveness

Are you looking for affordable handbags with an elegant look and an expensive price tag? If yes, relax, you got the sachet as expected. The quad-seal bag provides flexible storage options and a stylish finish, ensuring you get your money’s worth. The artwork used to produce the quad seal bag uses approximately 30% less material than other standard storage bags. Taking a typical storage box as an example, the open top is narrowed down on the quad seal bag. On quad seal bags, the open-top lid is reduced to a zipper, re-sealing tape, and more. For manufacturers concerned with flawless product branding, cost-effective product packaging/storage, and material usage, then you are in the right place. Quad sealed bags are your best choice.

5) 100% emptying capacity

Quad seal bags have perfect top openings. Whether you’re planning to store sugar, flour, medicine, or just about anything, with these bags you won’t have to strain to empty or refill. They open fully to allow the last bit of your product to be emptied. What a joy to use these bags.

6) Perfect storage

One of the basic uses of quad seal bags is their storage capacity. These quadrilateral bags are made from three layers of material, which are detailed in Chapter 6, Material Selection. Made with a laminated barrier, these gusset bags are designed to keep your products safe. If you’re trying to keep out UV rays, moisture, or oxygen, there’s no other choice. Aroma trapping, freshness preservation, and protection from contamination are the key services you will get from this quad seal bag. Manufacturers of coffee, tea and pharmaceutical products know the value of these bags. The protective measures taken during the manufacturing of these bags do ensure extended shelf life and product quality intact.

3. Plugins (Functionality)

Additional components are also available depending on your needs and the purpose of using the quad seal bag. If you’re packing coffee beans, you can use bags with vent valves. Additionally, there are quad pouches with zipper closures, tie tin closures for snack products, bag label closures, easy-open laser coring, and more. Every advertisement added is for your benefit as a manufacturer or product consumer. Below are detailed instructions for all necessary add-ons.

1) Tin paste application

As mentioned above, these bags are produced with the interests of the customers in mind. This is why the tin sticker add-on option is popular in quad seal bag production. Wouldn’t it be an important idea to be able to reseal a gusseted bag after opening it? The tin band application allows you to reseal your bag after each use until you have emptied it. The following are the main advantages of tin tie application.

- Tin straps ensure a uniform look across the top of your pouch.

- The bag can be resealed after each use.

- You can roll down the top of the bag with the help of a tin tie. This helps you to see how much product and what is left in the bag after use.

- Tin attachments provide a secure seal for easy product transport.

- Tin ties come in a variety of colors to choose from and use.

When ordering side gusset bags with tin straps, you must specify the size and color of the bag. Our company has a standard location where we can place tin ties. See the location in the chat chart below. However, targeting may change if you request it to be changed. When submitting your tin strip custom position, you will need to specify the distance from the top edge of the tin strip to the top edge. This will allow us to place the tin tie accurately. While allowing 1mm we use machines on our tin collar applications to maintain accuracy.

Standard Tin Strip Position

| Size | Place | Size length |

| 4 oz. | 1″ | 4.75” |

| 6-10 oz. | 1″ | 4.75” |

| 6-10 oz. | 1″ | 5.5” |

| 6-10 oz. | 1″ | 5.5” |

| 12-16 oz. | 1″ | 4.75” / 5.5” |

| 2 lbs. | 1.25” | 7″ |

| 5 lbs. | 1.5” | 9.5” |

For styles and sizes not shown above, please contact us to see if these options are available.

2) Hanging hole

Hanging hole application options are used to help extend shelf presence and increase storage space. Hanging holes are the perfect addition for retailers and inventories with limited storage space. Customers benefit greatly if kitchen shelf space is limited. Compared with paper tube food packaging, this is its biggest advantage. Although paper tube packaging can protect the internal products from being crushed at will, it cannot be perforated and hung like quad seal bags.

The hanging hole add-on is designed to make every product packaged on the quad gusset bag ready and point of sale. To ensure your product displays and displays stay relevant with the times, here are the hanging hole options or types to decide on when ordering quad seal bags.

A) Ergonomic handle

For those products that require additional carrying options, such as children’s treats, pet food, and some pharmaceuticals, the ergonomic handle allows you to insert your fingers for easy carrying.

B) Euro pocket hole

If your product requires a hanging option, we can produce quad seal bags with euro-style perforations. You’ll be able to hang your products nicely so customers can get a good look at them. This is an important add-on that customers and suppliers consider most necessary.

C) Round/circular punching

Round/circular punch holes are the most common hanging holes. They’re the perfect addition, enabling you to bring storage flexibility to your product. Any product you plan to store or display in a quad seal bag will work with this option. It’s just a matter of asking, all your gusseted bags will have round punch holes. Circular punch holes are essential when planning to enhance product presentation.

3) Valve application

When storing any product that emits gas, you must use a quad seal bag with a vent valve. In the case of roasted coffee, this add-on is indispensable. If you are a coffee roaster and decide to use a quad-seal bag with a vent valve, you will be able to package your coffee immediately after roasting. In order to produce quality bags with quality valves, we have two valve options available to us:

A) Wipf valve

Although originally Wipf valves were used for coffee, today they are used for other products. Wipf is a technological development using a liquid (silicone oil) membrane. When the packaged product (e.g. coffee) has released enough gas to create a pressure of 3 bar inside the bag, the valve opens to release the pressure. After the pressure drops to around 0.5 mbar, the Wipf valve reseals. This opening and resealing continue until the pressure inside the quad seal bag equals the pressure of the outside atmosphere. The great thing about Wipf valves is that they don’t let oxygen or moisture into your ostomy bag. They are one-way valves.

B) Goglio valve

The Goglio Group is the inventor and manufacturer of the Goglio valve. These are degassing valves that we can add a quad seal bag as one of the accessories. The Golgio degassing valve is a one-way valve. They consist of an elastic rubber disc, a polyethylene cover, an adhesive layer made of silicone oil, a polyethylene sheet, and finally a paper filler. A Goglio machine is used to assemble these high-performance valves and we use the machine to place them on the 4 side pockets.

These are the perfect add-on valves that will never let you down. They will allow degassing to occur until equilibrium of internal and external pressures is achieved, and eventually exclude moisture and oxygen. NOTE: The coffee will continue to release some gas after roasting for approximately 7 days. With the one-way valve, your coffee cube won’t burst from excess gas. The one-way valve allows degassing but not air, thus maintaining the freshness of the coffee. This way, your customers will be able to enjoy fresh, delicious and high-quality coffee. The following table shows the positioning distance of the degassing valve from the BB (bottom of the valve to the bottom of the quad-seal bag).

| capacity | valve position | notes |

| 16 oz. | 7″ | BB |

| 2 lbs. | 8.5” | BB |

4) Laser scribing

Are you a snack or candy manufacturer or own a factory? If YES, you need a simple opening quad sea bag with laser scoring. These additional features allow customers to easily tear the seal and access the packaged product. The laser-scored easy opening is a tear tab that can be placed on the top left or right of a four-pack bag. Such as travel snacks, children’s snacks, and so on. This tear notch does tear at least as far as the snacking products that try to make them the most convenient.

5) Matte and glossy oil coating

Would you like to have quad seal bags that resist wear and tear after repeated handling by your customers? Our matte and glossy oil coats will give you that protection. We are determined to produce bags with premium coatings to protect your quad seal bag material, not interfere with labeling and printing capabilities, protect your bags from the water, absorb light, and reflect light. We can add a matte finish to your bag if you wish. This will help protect your bag and stored products by reflecting any harsh light. Also, the coating will make your labels and images visible, don’t forget that they are attractive. We also have a glossy oil-coated (laminated) option. It is suitable for bags with a lot of text/drawings and protects your side gusset bags from scratches and scuffs.

6) Demetallization

Demetallization is the process of removing portions of a metalized material to create a transparent surface (window). What do you use to attract customers or make your product stand out on a crowded shelf? It will come in handy to make windows on your bags where customers can see the contents of the bag. We use water-based solutions or chemical cleaning to remove metal from your bag material. All of this is done by machine to keep the size, design, and position perfect. This is an excellent additional feature that is cost-effective even when doing metallization printing.

7) Front tap zipper

Quad-seal bags with front-tap zippers are becoming more and more popular with customers, the food industry, and the pharmaceutical industry. Front-tap zippers are accessories that make these bags very popular for their functionality. This bag can be opened and closed. This zipper helps to avoid contamination of the food or packaged product and allows the bag to be resold. Add-ons add to the usability and convenience of these bags. Finally, they provide a barrier for light and oxygen to flow into the bag.

Note: For any additional ideas, please contact us, and let’s discuss the best way to get your product in the best packaging to attract customers.

4. Types of quad seal pouch in the Market

We offer many types of quad seal bags for you to choose from. These bags are mainly named and differentiated by the type of material used. Here are the services we provide:

- Kraft paper quad-seal bag

- Quad-seal bag with valve

- Aluminum foil quad-seal bag

- Metalized quad-seal bag

- Transparent quad-seal bag

- Zipper quad-seal bag

- Front tap zipper quad seal bag

There are a variety of quad seal bag types to choose from depending on your bag usage. Purpose and durability should guide you when choosing a quad seal bag. Whether you’re handling dry pet food, catering products, or any industrial product, there’s a bag made just for you. Your quad seal bag manufacture will be happy to provide you with the type of bag you need. Below are the various types of quad seal bags that are right for you.

1) Quad sealed bag with window

Customers want satisfaction, and product manufacturer rules guide the production of our quad seal bags. So there are some products that customers need or want to see through the bag before buying. Because of this need, the idea of the window quad-seal bag type was invented. Customization is the philosophy we are committed to. No matter what design or function you need from this bag, let us provide you with the best. Depending on the type of items or products you want to carry or stock, you may decide to use a quad seal bag with a window.

Customers will be delighted to see the type, quality, and freshness of your products before purchasing. Take food pellets as an example; many customers want to see the state of those pellets. Seed food types like pet pellets, some treats, medicinal products, rice, and cereals are more eye-catching when looking through the bag. These bags increase product visibility and product presentation.

If you want all sides of the package to be opaque, but certain parts to be transparent or see-through, that’s okay too. See below. The quality of the quad-seal bags for windows is far from disappointing. Let’s talk about your ideas, your bag type, and the specifications you need: we’ll meet your needs without any hassle. Remember, we are on the same side here. Our idea is to keep our customers happy. Our quad bags are the first thing that attracts customers before they even taste the contents.

2) Aluminum foil quad-seal bag

Foil quad-seal bags are best when dealing with products that require special packaging conditions because they are multi-layer bags. They consist of approximately 3-4 layers, including an aluminum layer that provides extreme protection from heat, UV rays, oxygen, and moisture. These side gusset bags are used to ensure the long-term freshness of cereal, coffee, and tea products, not forgetting that they will stay on the shelf securely for a long time.

Foil quad seal bags have other added benefits that can make your packaging process elegant, durable, and attractive. They have some hidden reinforced seals on the rear edge. This is essential when resealing or folding the top after each use. Additionally, the surface of these bags provides additional space for product labeling/branding, hot stamping, and final vent valve placement. Foil quad seal bags also come in different colors. Any color you want will be provided to you. If you need this bag, place your order, and you won’t be disappointed. Our service will be up to the task.

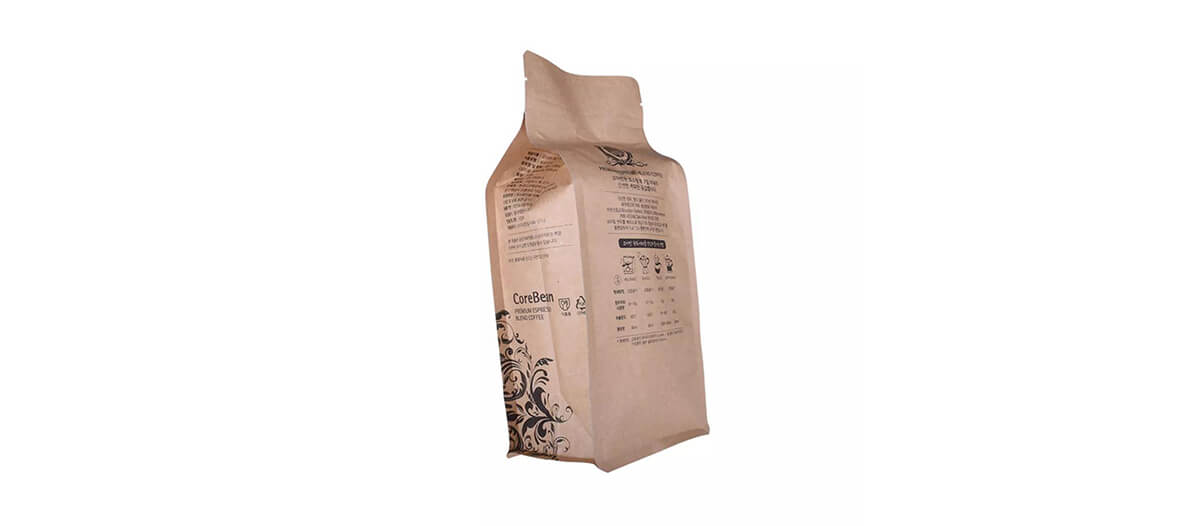

3) Kraft paper quad-seal bag

For non-refrigerated retail items, you will need craft quad seal bags. They have a heat-sealable zipper closure, are laminated inside, and thanks to their rectangular bottoms, are also shelf-stable for a long time. Finally, they are 6mm thick for food safety. They are named vellum because of the outer durable and robust paper used. They exist in various forms. Some are translucent and those are opaque. But the truth about these gusset bags remains; your product will be safe. The precise manufacture and material of craft quad seal bags demand their high availability.

They are packed in an inner foil and manufactured according to the latest lamination techniques, striving for perfection. This 4 side seal bag will keep out moisture, oxygen, oil, pipe contamination, or any contamination. They are ideal for pharmaceutical and food packaging, especially coffee and tea. 4 sided kraft bags are a favorite for coffee storage because of their natural look.

4) Metallized quad seal bag

If you need to store light-sensitive items or products, Metalized Quad Seal Bags are opaque and designed to accommodate such needs. Their prices are reasonable and their service is good. If you need an alternative to aluminum foil or clear polyethylene quad seal bags, metalized quad seal bags are an option. Don’t worry about the name. They are not made of metal; metalized gets its name from their special appearance; they look like metal. They are sometimes called “Mylar” due to their metallic appearance. Finally, branding, labels, and any printed designs will be more visible due to the opacity of the metalized quad seal pouch.

5) Square bottom quad-seal bag with E zipper

The square bottom quad seal bag with E-Zipper is an eye-catching and popular pouch. It is an overwhelming bag due to its low density. This quad seal gusset bag fits comfortably on a shelf without worrying about the possibility of it tipping over. E-zip square bottom quad seal bags are easy on the shelf and the E-zip attachment is a big plus. This cutting-edge E-zip addition puts this bag in a unique category. The zipper is a handy pull tab that makes this bag easy to pack and easy to open. Loose tea leaves and whole coffee beans fit perfectly in these bags.

You can get them in various colors, metalized, and clear poly or foil laminated types. Such a wide range of options ensures that your needs and requirements are well met. Finally, graphics, vent valves, labels, and hot stamping can be selected. All of these additional features are designed to make the Square Bottom 4 Side Seal Bag with E-Zip attractive and convenient for consumers.

6) Plantation pattern quad seal bag

Are you trying to get that chic and natural attention from your clients? One of the main reasons these sachets are called plantation pattern quad seal bags is because of the tea leaves and coffee beans they have on them. The design of those tea leaves and coffee beans does suggest an off-farm/plantation feel, it imprints or confirms freshness or purity. Appearance plantation design but metallization, foil material, and manufacturing concept ensure their usability. The craft paper used provides a wholesome texture as opposed to what you get from regular glossy bags. Finally, you can use hot stamping, product labels, and branding to give your product a leg up and sell.

7) Square bottom quad sealed bag

There is no obvious difference between the square bottom quad seal bag and the E-zip square bottom quad seal bag. They are perfect pouches, just lack the zipper attachment. They are suitable for coffee beans and loose tea leaves. Their square bottom keeps them firmly on the shelf. Inside, square bottom quad seal bags are carefully manufactured using suitable foil and metalized materials for quality reasons. Your products will have a long shelf life due to the use of high-quality packaging and materials. Finally, accessories such as valves, product brandings such as labels, and hot stamping can also be done on these square bottom quad seal bags.

8) Polyethylene quad-seal bag

Poly quad seal bags are best for items that are not intended to be on the shelf for long periods of time. They are prepared in such a way as to reduce manufacturing costs, yet still serve their intended purpose. Use all other commonly used quad seal bag materials except foil. These bring about a reduction in production costs and a media protection barrier. These bags are designed to protect products from oxygen and moisture until they are used or ready to use. But all in all, your desired goal will be achieved without any suspense. Polyethylene quad seal bags are ideal for packaging coffee, tea, biscuits, snack mixes, nut and powder mixes, and other intended products. Finally, they are manufactured in various colors and sizes according to the requirements of the customers.

9) Quad seal bag with front Tap Ziplock

Are there any products you worry about when you know your kids will be home that day? We do understand your concerns. That’s why we developed the quad seal bag with a front self-sealing zipper to keep children out. The addition of a pull-tab zipper lock makes it difficult for children to open these bags and gain access to the packaged product. This new option is uncomplicated but convenient. The tab lock is located just above the zipper. They’re used to make it difficult for kids to open the bag but within easy reach for older quad-seal bag users. Quad seal bags with front zip closure are perfect for household chemicals, pharmaceutical products, nutritional supplements/vitamins, laundry, and detergent products, or anything to which you don’t want your kids to have access.

10) Aplix/velcro zipper quad seal pouch

The Aplix/Velcro Zip Quad Seal Bag is the new custom bag designed for convenience. They contain easy locks made from hooks. Hook-to-hook closure technology makes these bags one of the most flexible and resellable corner seal bags available. They are easy to open as the hooks are designed to be easily undone, ensuring maximum bag opening and easy reseal. This easy-to-lock idea from Aplix has helped us create one of the most secure quad seal bags of all time. This bag has grown in popularity due to its efficiency and ease of use. Plus, the Velcro Zipper Quad Seal Bags are easy to reseal and help protect packaged products from contamination. The link below shows how easy our Aplix / Velcro Zipper Quad Seal Bags are to use.

5. Application of quad seal pouch?

Compared with ordinary gusset bags, quad seal bags are more stable on retail and wholesale shelves and more attractive to customers. The small size of these bags allows for the proper use of the limited shelf space available. Mostly, quad seal bags are used for packaging tea, coffee, and other food products. The product packaging process has changed a lot over the past few years. As the world evolves, so does the packaging process. This change can be attributed to three main areas:

- Manufacturing and Technological Change

- Financial investment terms and brand equity

- Shifts in consumer buying habits

For this reason, we have developed quad-seal bags to meet your needs. Made from high-quality materials, they are versatile and have several advantages over other bags. If quality packaging is your concern, whether as a manufacturer, retailer, or store owner, this eBook will guide you to the ultimate solution for quad-seal pouch-based consumer packaged goods (CPG).

Compared to other types of bags; for example, multi-layer paper bags as well as bags made of plastic materials, quad-seal bags are the most sustainable. In this section, you’ll learn about the various uses of quad seal pouch. As mentioned earlier, these are multipurpose bags. They are used by various industries such as the beverage industry, food industry, medical industry, biotechnology industry, etc. They are used in product packaging, storage, storage, and transportation. Here are some of the products packaged in these bags:

- coffee

- tea

- cereals

- pet food

- human food including flour

- medical products

- sweets and treats

| Product/Item | Quad-seal bag type |

| coffee | Windows, aluminum foil, plantation patterns, metalized quad seal bags, etc. |

| tea | Windows, foils, metalized quad seal bags, etc. |

| cereals | Window quad seal bag |

| pet food | Square bottom quad seal bag with E zipper |

| human food | Quad seal pocket with front zip |

| medical products | Foil, Metallized, Aplix / Velcro Zip Quad Seal Bags |

| sweets and treats | Window bags with E zipper, metal bags, and square bottom quad seal bags |

Extensive use says it all. If it weren’t for the quality, uniqueness, and durability of the quad seal pouch; they wouldn’t be in those critical areas of use. The quad-seal bag’s rectangular bottom and reinforced gusset hold 8 oz. Up to about 40 lbs. Their extended gussets make them suitable for products that require high-volume storage. But that doesn’t mean they’re heavy. They are lightweight, well-reinforced, and constructed for their intended purpose. Quad seal slip pockets come in different sizes.

Note: The choice of a quad-seal bag depends on its application and customer requirements. Whatever our customer needs, they will get it. We manufacture different types of flexible quadd corner panel sealable bags. The table below will help you understand the various details to consider when ordering these packages.

| weight (g) | weight (ounce) | width | high | bottom | thickness | MOQ | deliver goods |

| 150 | 5.29 | 3.54” | 7.4” | 2.17″ | 60-180 microns

2.5-7.7 million. |

30000 | 30-35 days |

| 250 | 8.82 | 4.72″ | 8.1” | 2.36” | 60-180 microns

2.5-7.7 million. |

30000 | 30-35 days |

| 500 | 17.64 | 4.92” | 11.8” | 2.76″ | 60-180 microns

2.5-7.7 million. |

30000 | 30-35 days |

| 1000 | 35.27 | 6.89” | 12″ | 3.94” | 60-180 microns

2.5-7.7 million. |

30000 | 30-35 days |

| 2000 | 105.82 | 8.26” | 15.16” | 4.72″ | 60-180 microns

2.5-7.7 million. |

30000 | 30-35 days |

NOTE: Measurements are in inches but are based on theoretical data. Actual dimensions may vary slightly, but not large enough to affect the use or quality of the quad seal bag. If you need a bag to protect your products from UV rays and seal out oxygen or moisture, we have you covered. That’s why these beautiful bags are produced. With that in mind, let’s turn to the benefits.

6. Material Selection

First of all, the construction process and technology of the quad-sealed bag are determined by the requirements. Material lamination is the most important part of any particular quad seal bag construction. Manufactured perfection can be attributed to technical know-how. Are you worried about blocking UV rays, oxygen, and moisture? These quad gusset bags have the sound insulation you need. For products that require fragrance protection, side gussets are essential. They are designed to maintain the aroma for as long as the product is on the shelf. They are very important for the storage of tea and coffee products. Before getting into the material details, you need to know that the Quad Ziploc pouch layers are made using three types of materials. They are:

- Polypropylene (PP) or polyethylene (PE) for thermoplastics, derived from petroleum products

- Polyester (a form of synthetic polymer)

- Metal foil, normally aluminum

All three materials are combined in chemically proven proportions to make a premium side gusset bag. The following is a more detailed explanation of the combinations. Most bags are made by laminating several layers of film together to form side panels. In most cases, there are usually three alternating layers, as follows:

- Inner membrane: LLDPE easy to peel

- Barrier film: VMPET or AL, NY

- Outer layer: matte PET, OPP, PET, natural color craft paper

1) PET (polyethylene terephthalate)

This is a type of polyester commonly used for exterior restraint work. This material provides excellent puncture and tear resistance for the 4 corner pockets.

2) AL (aluminum)

This is an added type of metal that makes these bags insulated from oxygen UV rays.

3) VMPET (Vacuum metalized polyethylene terephthalate)

This is a material formed by adding AL (aluminum powder) to PET. This VMPET acts as a UV, moisture, and oxygen barrier if aluminum is not used alone.

4) LLDPE (Linear low-density polyethylene)

LLDPE is used when making clear quad seal bags or white bags. It is an important material due to its heat sealability, stiffness, and tear/puncture resistance. LLDPE material is used as the innermost layer.

5) SIOX-PET (Silicon dioxide – polyethylene terephthalate)

The silica is heated, evaporated, and forms a thin layer in the PET, strengthening it for strong quad seal pouch lamination.

6) PVDC (Polyvinylidene chloride)

PVDC is used to increase the barrier capacity of PET or BOPP. It helps to increase the permeability of these bags to oxygen and moisture and to protect the stored product aroma. PVDC provides the perfect gusset pocket coating.

7) EVOH (Ethylene vinyl alcohol)

EVOH is the perfect barrier to oxygen, moisture, carbon dioxide, and UV penetration, and keeps your product aroma.

8) Xuan paper

If you need a good-looking, generous, textured, and good-looking bag, then we have rice paper materials for you. The material will satisfy your wishes.

9) Kraft paper

Kraft paper material is mainly used for packaging coffee or tea. It is used as the outermost layer to give your quad seal bag a natural look. This means away from the concept of the farm

10) CPP (Cast polypropylene)

CPP is an important material that gives these 4-sided gusset bags flexibility and proper sealing and helps prevent them from warping. Bags made of CPP material have a high gloss appearance and excellent heat resistance.

11) OPP (Oriented polypropylene)

OPP is the material with the best high-temperature resistance. This does help your quad pack resist the heat to a certain degree.

12) PA (Polyamide)

We use polyamide because it has excellent oxygen barrier properties and perfectly captures the aroma of the packaged product. On a typical 4-side seal bag construction, PET/ MET PET/ MOPP (Matte) material is used as the outer layer, VMPET or AL is used as the barrier layer and the middle layer, and finally, LLDPE is used as the innermost layer.

7. Production, Artwork, and QA

These quad seal gusset bags are made with a continuous web of material to ensure a flawless end product.

1) Production plan

The production process of Quad seal bags is mainly based on customer satisfaction. So let me tell you how we do business for mutual benefit. Here is the outline:

A) Need analysis

After placing your order via email, phone, or in person visiting the premises, you will be met by one of our qualified customer service staff. Those who send emails, they will get a response within 24 hours during business days. The main job of the customer service staff is to bring you to the sales department which will take note of all your requests and designs for the type of bag you want. All questions will be focused on the purpose of the package, but make sure to note down every detail you need. They will need detailed information about the quantity, size, and color, estimated date of the order, shipping method, and delivery country (port or airport). After that, they will forward your product model order.

B) Research and development

At this stage, your order will be analyzed, a design drawing will be drawn up, and each product blueprint will be considered. When all the right ideas and designs are done, your brand and artwork will follow. After considering every detail you need, the production of your quad seal pouch begins.

C) Production

Our production facilities are stocked with the latest machines for the production of side slip pockets. Our products require three main steps. Humans program them, but machines do most of the work.

D) Feed section

Here, flexible materials are rolled up. Some feed rollers are used to pull and push packaging materials through machines that occur through the bag-making process. The dancing system is used to maintain a constant movement of the material film. We have precise machines because we focus on quality.

E) Sealing section

When the dancer keeps the membrane moving, the sealing process begins. The sealing elements are kept at a controlled temperature for a perfect seal, and in the process, the gusset is also well-made. The speed of the sealing process depends on the type of material used and the desired bag design. After the sealing process is completed, the quad bag is cut into a quad seal bag.

F) Slitting and bagging operations

Once the sealing is complete, the next process, which is bagging and cutting, begins immediately. The speed here also depends on the machine type and setup. Finally, the fittings that are attached to the main unit at the bottom are used to secure additional functions such as zippers, hanging holes, valves, etc. Our company prides itself on seven high-speed automatic bag-making machines, the latest color printers, and solvent-free laminating machines. You don’t have to worry about delivery.

G) Printing and labeling

The print is a noble thing, and you can’t ignore your quad bag. The printing and labeling of quad seal pouchhelp attract customers. Our factory is equipped with relevant machines for this. Most often, the material film is printed before the sealing occurs. The printing and labeling in our factory are done by machines such as semi-automatic labeling machines, automatic labeling systems, and print labeling machines. They make our job easier and bring uniformity in color, size, label, or writing position.

2) Works of art

After the production is completed, work on the artwork design to make your bag more attractive. Any artwork is done using drawings, 3D effects or VI designs according to customer requirements. If done on a computer, here is the design of the Quad gusset bag. Make design templates with top-notch perfection to ensure that every size, dimension, and structure is well accounted for before being sent to production or manufacturing. Below is a quad seal pouch design template.

3) QA and testing

After the production is completed, the bags will not be shipped immediately. As part of our quality assurance process, they must undergo extensive testing and inspection to ensure that quality and customer requirements are met. Quality assurance requires proof of defects throughout the production process to ensure the quality of the quad slip pockets. Note, however, that while it is not possible to achieve a 0% defect rate, our defect rate maybe 1-3%. In addition, since it is not possible to check one by one, sampling is carried out during product testing. Defects fall into three categories:

- small defects that will not make the bag unsuitable for use

- the main deficiencies that should be corrected

- serious defects that make the bag unsafe.

Here are the techniques we use to check quality.

A) Tensile test

A tensile test is an inspection whose purpose is to determine the breaking strength of the materials used, especially PP. When serving products such as sugar, rice coffee pharmaceuticals, or any heavy product, you need sturdy packaging, and that’s exactly what the quad-seal bag provides. Tensile testing ensures that you get a strong, durable, and durable bag.

B) Heat seal test

This test ensures that the seal can withstand any tears, extending shelf life. If the cut-sealed sample meets the expected strength range, your bag is ready to use.

C) Coefficient of friction tester

This test procedure is used to test or measure the sliding resistance of the bag. The materials used are tested to ensure that Quad bags fit on the shelf without fear of them slipping off.

D) Gas chromatographic detection

This ensures that the quadrangular slip pockets produced hold the aroma well and isolate oxygen. If you need a bag that can block oxygen, you have no choice. Quad seal bags are the best choice for the bags you can make. All these quality assurance tips must be checked before shipping your luggage to you. The main purpose of quality assurance testing is to ensure that quality service is provided to our customers.

After manufacturing, testing, and all quality aspects are completed, the bags are stored for a while in our factory storage facilities before being shipped. Our storage facilities are clean and tidy, top-notch and your luggage is safe. After completing all transportation logistics; everything in this happens within the agreed time, and our transport vehicles will deliver your luggage at the port or airport to the place where it is ready for transportation.

8. Packaging, Filling, and Sealing

This is the last but vital part of your packaging quality and a perfect product. Regardless of the quality of your quad-seal pouch, the packaging, filling, and sealing should be carefully checked.

1) Packaging of quad seal bags

Some complex but simple machines do these packing, filling, and sealing. The type of machine you want to choose depends on the speed, workload, space, and height of your facility. There are two main types of machines for packaging, filling, and sealing.

- Vertically Formed Fill Seal (VFFS)

- Horizontal Forming, Filling and Sealing Machine (HFFS)

The main difference between the two machines is the name. The first runs vertically, with a smaller footprint but a longer height. The latter works horizontally and takes up more floor space but has a lower height. These machines can fill and seal about 30 -300 bags per minute, but some machines can be higher. The speed of the experience depends on the quality of the product and the type of product filled in the quad-sealed bag.

2) Filing of quad-seal bags

Whether you use HFFS or VFFS, the filling volume or discrete tea, coffee, or any product is measured by the filling machine and placed in the bag. A third-party manufacturer is a manufacturer that provides fillers that contain augers to properly measure the amount of product. However, you can order both devices from the same packaging equipment manufacturer. If you order these filling heads from one manufacturer, your job becomes much easier because you only have to make a quote once, and the manufacturer will be responsible for integrating the machine well into a cohesive system.

3) Sealing of quad-seal bags

A quad seal pouch is a last but noble step. At this point, perfection is required to ensure that the seal is complete. For example, before the sealing is complete, the machine must remove oxygen to ensure the shelf life and freshness of the product. One of the sealers, VFFS, is highly recommended for sealing coffee. For products that require zero oxygen retention, modified atmosphere packaging (MAP) is used. MAP allows unwanted carbon dioxide to escape before sealing. Second, nitrogen is sometimes flushed into the bag before filling and sealing to ensure that oxygen is completely displaced.

Regarding sealing and filling options, we have the following options.

A) Continuous VFFS packaging machine

The packaging machine can pack 300 bags per minute ranging in size from 50 mm x 90 mm to a maximum of 300 mm x 1000 mm. It has a power supply of 6 kVA and a bar-bar. This is one of the high-speed machines around.

B) Intermittent motion VFFS M500 packaging machine

For all large quad bags, this is the machine we use. It can fill and seal 70 large bags per minute with a minimum size of 150mm x 100mm and a maximum size of 500mm x 600mm. It requires a power supply of 208-240 V and an air requirement of 12-8 SCFM. However, there are VFFS machines with intermittent motion. Thus, the mentioned machines come in handy in the packaging, filling, and sealing of quad-sealed bags.

9. Conclusion

Human food, pet food, pharmaceuticals, and pharmaceuticals all require perfect storage. Quad seal pouch have you covered. Remember, Quad Seal bags can be customized according to your requirements; all you need to do is specify the size, design, type, and other important specifications that you think are essential for your bag. The advantages of ordering quad bags from us are as follows:

- Because it is ordered directly from the factory, it will save some costs.

- Your quad seal bag will have a spoken word advert.

Your flexible packaging supplier should guarantee to provide you with quality products to attract customers.